The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

Motorcycle Parts New Zealand Specialists Things To Know Before You Get This

Table of ContentsWhat Does Motorcycle Parts New Zealand Specialists Mean?Rumored Buzz on Motorcycle Parts New Zealand SpecialistsThe 9-Minute Rule for Motorcycle Parts New Zealand SpecialistsFacts About Motorcycle Parts New Zealand Specialists UncoveredMotorcycle Parts New Zealand Specialists - An OverviewMotorcycle Parts New Zealand Specialists for DummiesThe Basic Principles Of Motorcycle Parts New Zealand Specialists Not known Details About Motorcycle Parts New Zealand Specialists

So, reach out to one of our professionals today.CNC machining technology is promptly becoming the focal point of several various production processes around the world as a straight result of its numerous benefits over various other methods. Furthermore, the markets that make bikes have actually jumped on board with this trend. One of the most cutting-edge business are currently creating their engine components and wheels using machining techniques originally developed for motorbike parts.

On the other hand, the effects of industry are the primary emphasis of this post. Allow's obtain straight right into it. You might be questioning why we utilize. It is not tough to fathom the variables that brought about this outcome. Since we have your attention allow us discuss the reasoning behind this modern-day development in the motorbike manufacturing industry.

All about Motorcycle Parts New Zealand Specialists

In addition, you have total control over the look of the elements, also down to the min details. Occasionally, motorcyclists might decide to spruce up their adventure by installing aftermarket components or changing the bike's transformation.

The Of Motorcycle Parts New Zealand Specialists

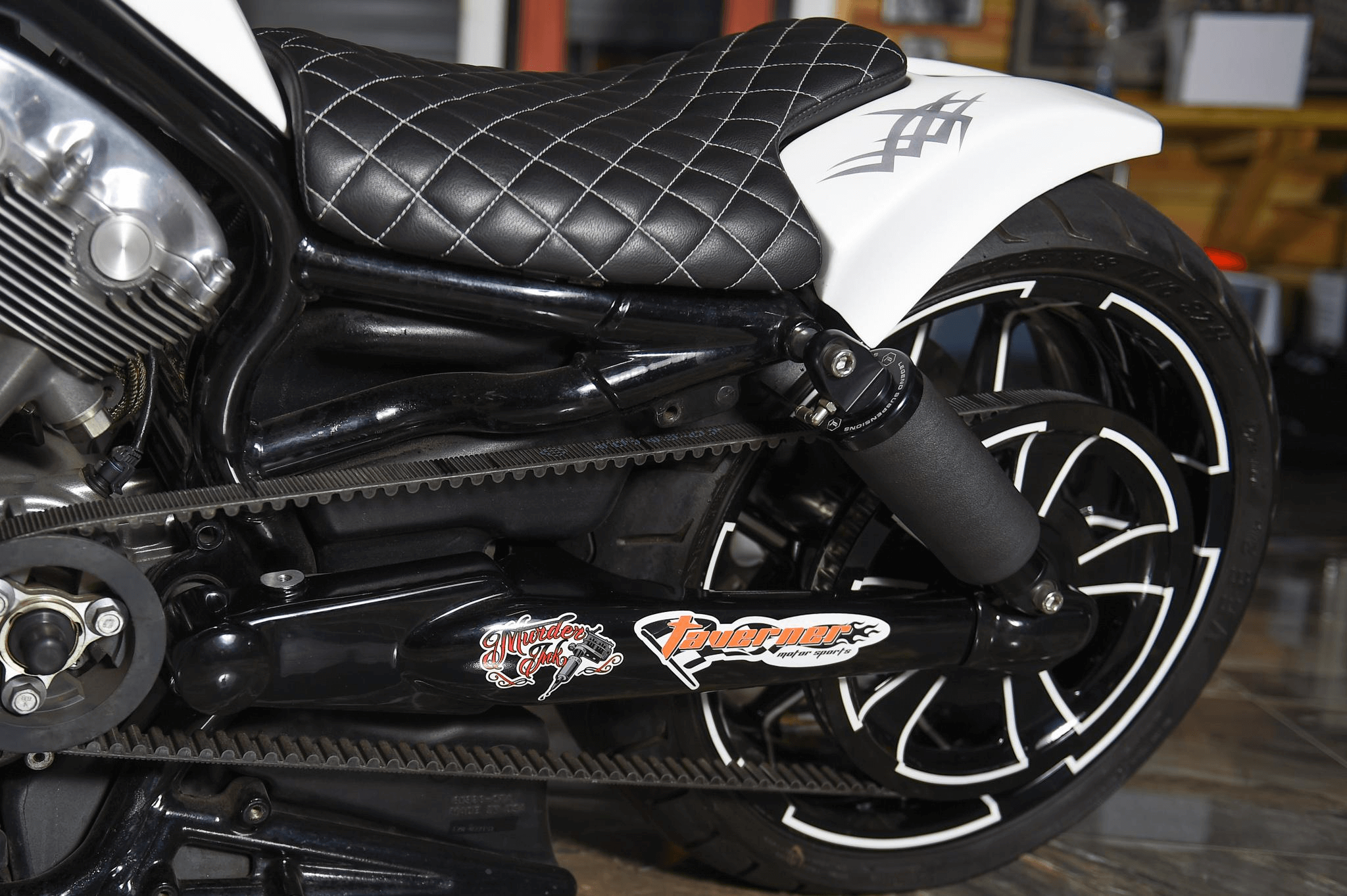

CNC machining might be used to make virtually all of a motorbike's metal and plastic parts. To proceed, we'll review several machined components for motorbikes. As opposed to those on cars, wheels on motorbikes have a tendency to be much more noticeable. Because of this, the bike's appearances might be boosted with the suitable customization of these wheels.

Milling procedures are made use of to get the wanted level of wheel personalization. One more aspect of the motorbike that may be personalized is the tires.

The Greatest Guide To Motorcycle Parts New Zealand Specialists

When it concerns a lorry (or a motorcycle), one of the most vital component is the engine. A number of people suggest to it as the "heart" of the vehicle. On the other hand, the camshaft, the cylinder head, and the pistons have a tendency to be detailed and need designs with a high degree of precision.

Lights is another facility aspect of customization. Usage only premium products, however, given that these lights are crucial for the safety of motorcyclists and other chauffeurs or people when traveling, especially during the night. Motorbike fronts lights have three almosts all: the bulb, or light, the lens, and the real estate. Specifically, we customize the lens and the real estate.

Milling processes with a perfect finish would certainly cause the lenses having a reflective top quality that resembles that of a mirror. The cover, on the various other hand, is not composed of breakable materials; rather, it is created out of challenging polymers that can be machined into more complex patterns.

An Unbiased View of Motorcycle Parts New Zealand Specialists

Bike makers often cast these parts, but only for the manufacturing of bespoke parts. Machining on five axes in today's globe is the methods by which any kind of design form might be realized.

Pick Runsom for your customized bike components! We have the capacity to produce difficult and stylish components making your navigate to this site motorbike matchless.

Below are a few instances of metals usually made use of in motorcycle component machining. Light weight aluminum is the primary product utilized by firms focusing on generating customized motorbike components to develop most of these parts. In the past, we would certainly build our engines out of actors iron. On the various other hand, light weight aluminum is quickly coming to be the material of choice, partly due to the fact that it is much more lightweight.

Zinc refers to another metal that is very light in weight and has great machining top qualities because of its high mechanical toughness. This material might be created into nearly any type of shape and maintains its dimensions well. Even mission-critical components that require a high degree of accuracy may take advantage of their usage.

Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

One more steel that sees hefty usage in the manufacturing of CNC-customized elements is magnesium. It is among the lightest metals that are now accessible and has outstanding machinability attributes and toughness proportionate with its reduced weight. One of the downsides of magnesium is blog here that its dust may quickly catch fire.

As a result of its remarkable machinability and weldability, stainless-steel is an alloy that is specifically well-suited for CNC processes. They have fantastic deterioration resistance and a high visual appeal. Their most typical usage in generating numerous motorcycle elements is bolts, such as screws click here to read and screws. Their reduced susceptibility to oxidation and rust makes them perfect for this use.

Indicators on Motorcycle Parts New Zealand Specialists You Should Know

It seems that CNC transforming and grating are the fundamental processes. In enhancement, it calls for maintaining bars of product, most typically plastic or metal, in setting and then twisting a cutting device to remove areas of the product as the material is transformed.

These techniques are similarly essential and generate parts with high accuracy and regular high quality. The procedures help boost the total quality of the machined bike parts.

Examine This Report about Motorcycle Parts New Zealand Specialists